Abstract

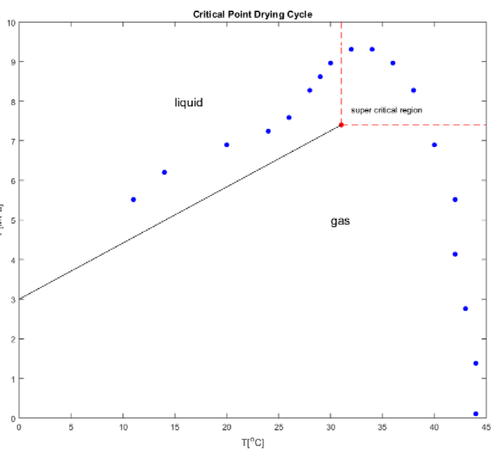

In this report I monitor a full successful cycle of critical point drying (CPD) run for drying MEMS sensors after wet release using KOH etching. The pressure and temperature of the CPD tool (Tousimis) is monitored during the process and plotted in a P-T diagram with \mathrm{CO_2} critical point. A few notes for higher yield in the drying process are mentioned in this report as well.

Citations

Error during add file

This DOI is not valid until the version is published on Zenodo.

DOI 10.5281/zenodo.3933312

Statistics

3386

1243

2

Comments (7)

Log in to comment & reply

Mohammad J. Bereyhi

This test was done in 2019.

Johneph Sukham

Dear Muhammad, I am now currently facing challenges related to CPD of our sliced nanobeam structures as I always observed that they always collapse together. I really got the motivation to try out the few notes you mentioned on the article related to filling in ethanol below the purge hole in the chamber and I was always filling them up above the fill holes. Could you elaborate a little bit your research experience in this regard ? Regards, Johneph

Mohammad J. Bereyhi

Hi Johneph, I have also experienced low yield when the ethanol level is too high and above the fill valve’s output since the large turbulence created during the filling can be destructive for sensitive in plane sticking. This would very much help (at least it did for us at EPFL). The idea here is to avoid the initial harsh flow of CO2 into the CPD chamber when the tool starts the filling procedure. I hope this helps. I will be curious to know if this improves your yield as well.

Johneph Sukham

Hi Mohammad, I have a quick question on the CPD: how much is the purge time that you used ? Regards, Johneph

Mohammad J. Bereyhi

Hi Johneph, We usually purge for 20 min.

Amirali Arabmoheghi

Do you use a custom sample holder?

Mohammad J. Bereyhi

Yes, we use a custom-made holder to keep the samples submerged in liquid at all times.