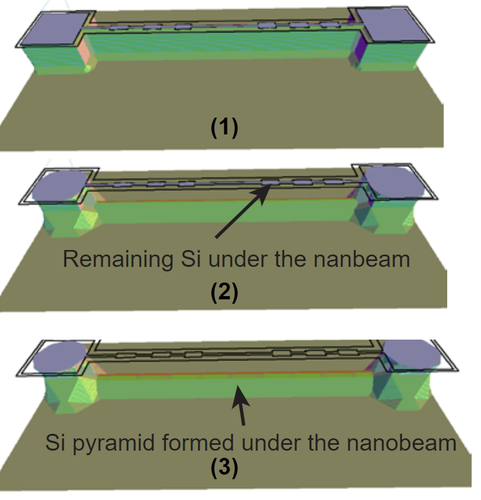

Here I explain the KOH simulator software (ACES) from University of Chicago [1] for a chain process of DRIE followed by KOH undercut. This software is very simple yet power to understand how Si etching works and design the mask to optimize the etch speed and crystal planes [2].

Results (5)

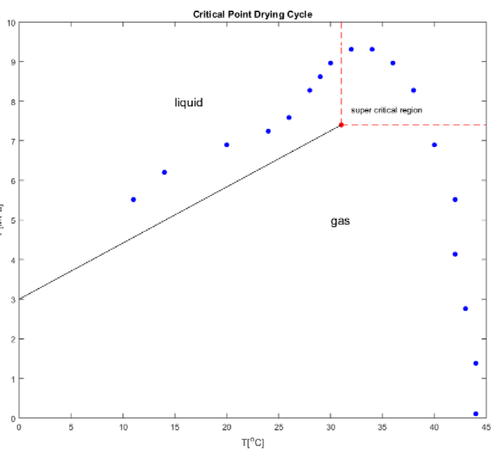

In this report I monitor a full successful cycle of critical point drying (CPD) run for drying MEMS sensors after wet release using KOH etching. The pressure and temperature of the CPD tool (Tousimis) is monitored during the process and plotted in a P-T diagram with \mathrm{CO_2} critical point. A few notes for higher yield in the drying process are mentioned in this report as well.

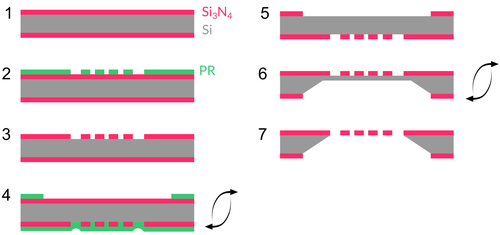

A fabrication method for large-area, high-stress LPCVD \mathrm{Si_3N_4} membranes is presented. These devices can be used as mechanical resonators with very low dissipation, exploiting dissipation dilution. A phononic crystal pattern allows to work with a high-order localized mode, shielded from acoustic radiation in the substrate. The procedure is amenable to most research clean rooms, requiring conventional lithography techniques and wet etching in KOH for device undercut.

Alumina (\mathrm{Al_2O_3}) films are widely used in photonics and superconducting circuits as an etch stop or passivation layer. In silicon nitride (\mathrm{Si_3N_4}) fabrication, a widely used etching recipe is dry etching using a mixture of \mathrm{SF_6/CHF_3} gasses. In case of multi-stacked materials, one might be interested to etch the \mathrm{Si_3N_4} layer with an stop layer to protect the rest of the stack from the etching step. \mathrm{Al_2O_3} is a great etch stop layer for \mathrm{Si_3N_4} ...

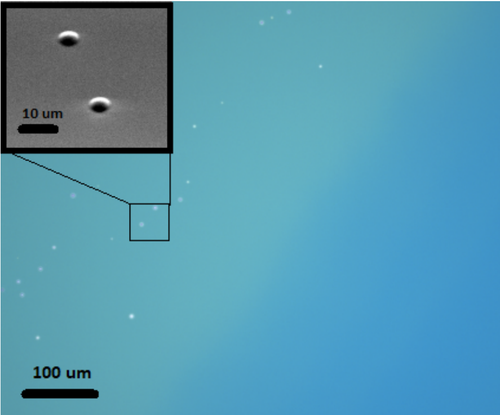

Releasing mechanical structures is a fundamental step in MEMS processing. Given the wide usage of silicon nitride ( \mathrm{Si_3N_4} ) on silicon (Si) carrier due to high stress and high mechanical Q factors, high etching selectivity between \mathrm{Si_3N_4} and Si is very crucial for the release process. Here we demonstrate that UV light from ambient light sources in a cleanroom environment (EPFL - CMi) can increase the etch rate of \mathrm{Si_3N_4} ...

Results per page