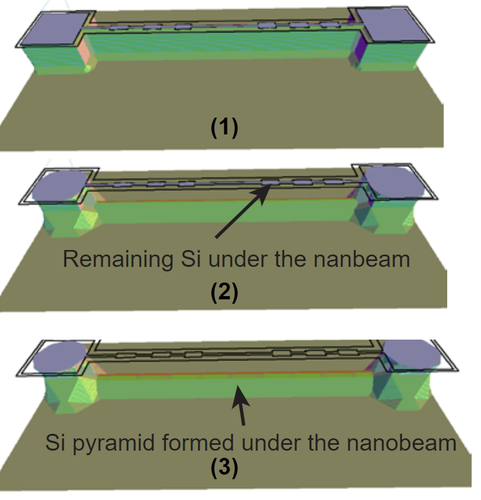

Here I explain the KOH simulator software (ACES) from University of Chicago [1] for a chain process of DRIE followed by KOH undercut. This software is very simple yet power to understand how Si etching works and design the mask to optimize the etch speed and crystal planes [2].

Results (5)

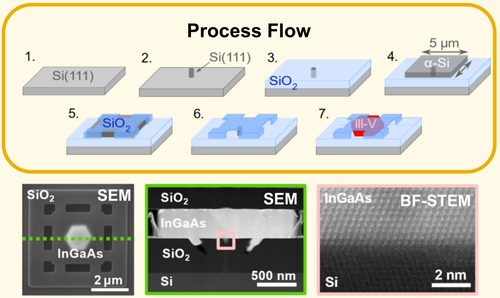

This work was presented at the Nanofabrication Photonics Online Meetup, 16-18 May 2021. Template-assisted selective epitaxy enables the local integration of group III-V semiconductors on Si with high material quality for nanophotonic applications. Here we demonstrate evidence of room temperature lasing at 1530 nm for a monolithically integrated InGaAs whispering gallery mode cavity on Si with a thickness of 300 nm and a diameter of 1.5 µm. These devices can potentially be scaled down further ...

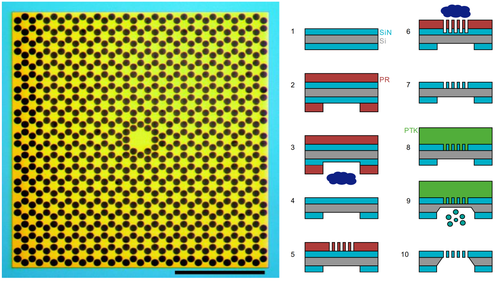

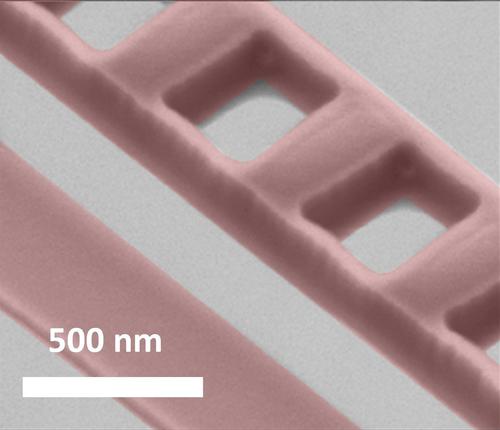

Thin silicon nitride nanomembranes are attracting growing attention following a novel fabrication method which consists in patterning them with a phononic crystal. In engineering the vibrational mode profile, the dominant mechanisms of loss, radiation loss and intrinsic material loss, are simultaneously addressed and mitigated. The fabrication method employed by the optomechanics group at the Laboratoire Kastler Brossel is here presented, only employing basic lithography techniques and wet etching processes.

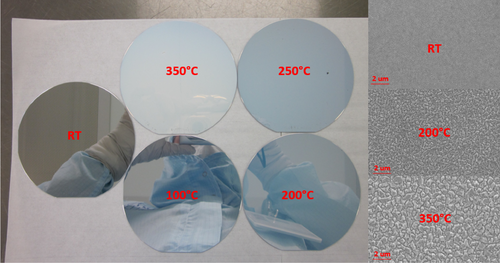

Here we present our study of the stress dependence in Al thin films on deposition conditions. We consider two types of Al 100-nm thick films: E-beam evaporated films and films obtained by magnetron sputtering. We investigate the Al film stress hysteresis in the environment with slowly increasing and decreasing temperature, i.e. during the gradual annealing. We consider the effect of deposition temperature on the film stress and grain size. We conclude that the annealing of ...

This is a method to improve the quality of lithography - in particular electron beam lithography (EBL). During an EBL exposure the electrons undergo different scattering processes. One scattering process that plays an important role is the back scattering of the electrons from the substrate or different stacks of thin film present in the exposure stack. As a result the actual dose that the resist sees is quite different that the original exposure dose. This ...

Results per page