We highlight some stability issues in high-surface-area and high-aspect ratio gold nanostructures fabricated using inorganic adhesion layers on silica substrates. We ascribe these problems to capillary and surface effects and show the use of organic silane self-assembled monolayers to improve the long-term stability of such structures.

Results (5)

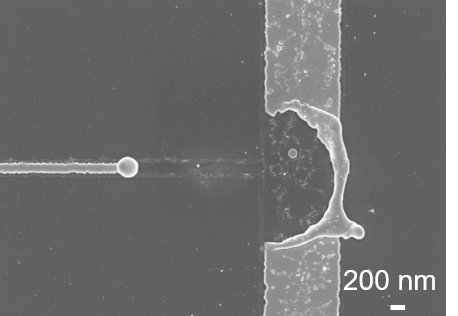

We describe a fabrication process for electron beam lithography (EBL) and the following pattern transfer steps on transmission electron microscope (TEM) grids. For demonstration purposes, we use commercial off-the-shelf TEM grids consisting of a thin suspended silicon nitride membrane on a silicon frame supporting substrate. For the pattern transfer, we demonstrate both an additive patterning technique with metal deposition and lift-off, and a subtractive patterning technique with reactive ion etching. This process could enable direct ...

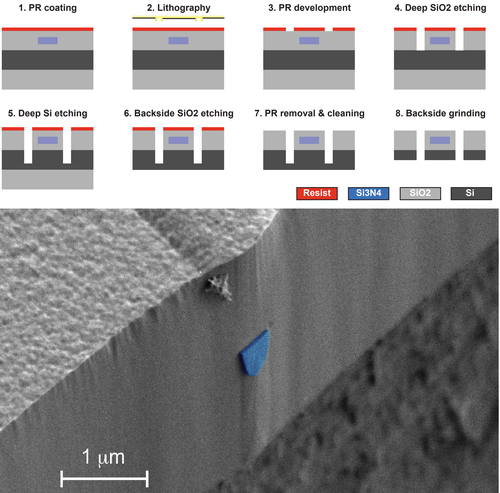

This short article describes a method to separate a wafer into photonic chips or dice, using dry etching and backside grinding. This method enables smooth chip facets that are advantageous for edge coupling with fibers or other chips.

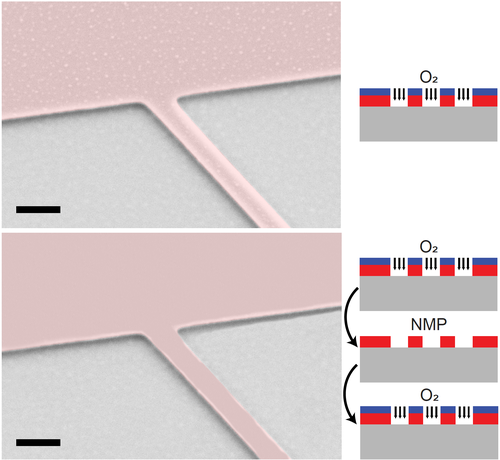

Resist removal is an essential step for multi-layer lithography processes where a clean and contamination-free surface is essential to avoid shadow etching patterns from resist leftovers. We show that a short \mathrm{O_2} plasma exposure followed by a full NMP solution cycle removes the resist fully and leaves the surface contamination free.

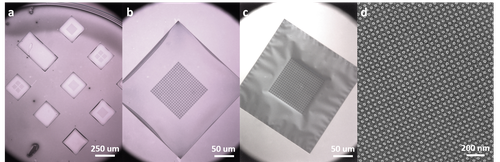

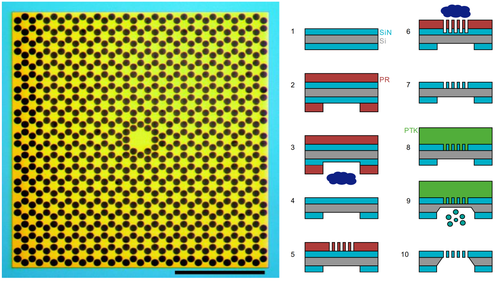

Thin silicon nitride nanomembranes are attracting growing attention following a novel fabrication method which consists in patterning them with a phononic crystal. In engineering the vibrational mode profile, the dominant mechanisms of loss, radiation loss and intrinsic material loss, are simultaneously addressed and mitigated. The fabrication method employed by the optomechanics group at the Laboratoire Kastler Brossel is here presented, only employing basic lithography techniques and wet etching processes.

Results per page